Silage Cast Films

We produce silage cast film in our modern production facilities. This assures that we will have the right type of product to offer our customers regardless of the application. Our silage film manufacturing facilities are ISO certified to ensure we produce the highest quality products consistently and cost-effectively.

Description

Silage films are used primarily to preserve silage, hay and maize. They maintain the nutritional value of the contents and inhibit undesirable fermentation processes. To reach the needed properties that ensure protection throughout the duration of outdoor exposure the films require good resistance against weathering.

Specifications

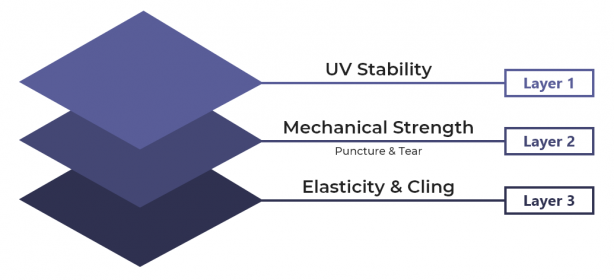

This Technical Specification concerns the Polyethylene, 3-layer, LLDPE & mLLDPE SILAGE film manufactured with the use of the CAST film extrusion technology.

| Thickness (μm) | 20 | 25 | 30 |

|---|---|---|---|

| Width (mm) | 250 / 500 / 750 | 250 / 500 / 750 | 250 / 500 / 750 |

| Roll Length (m) | 1800 / 1800 / 1500 | 1800 / 1800 / 1500 | 1800 / 1800 / 1500 |

| Roll Weight (kg) | 9 / 17.5 / 21.5 | 11.50 / 22.65 / 28.65 | 12.50 / 25.50 / 31.50 |

| Available colors | Milky White | Green | Black |

It is possible to manufacture the film of custom thickness or length after having consulted and confirmed with our customer.

The Bladex Wrap excellent Slide high-end silage film product range offers high-quality products for the best possible silage results and highest forage quality.

Properties

The 3 layers that make up Bladex wrap excellent film offer the following properties:

Multi-layered Film

A 3-layer film offers a very high oxygen barrier which has a positive influence on fermentation and conservation of the silage.

Elasticity

You should be able to stretch the film by up to 400 % on the wrapper.

UV Protection

Bladex Wrap is manufactured to suit the various climatic conditions of the world. This ensures that Bladex Wrap can withstand extremes of temperature to keep bales safe and secure during storage.

Resistance

A tear and puncture resistant film will protect the bale during wrapping and in transit. The exceptional puncture and tear resistance of Bladex Wrap enables the film to cope easily with the impact of the shoots and stalks associated with stemmy, forage crops.

Tack Characteristics

Bladex Wrap excellent silage films assure outstanding tack characteristics even in extremely hot temperatures. With our excellent wrapping properties, the film clings instantly and firmly to the bale, exemplary pressing the air out of the bale and allowing fermentation to begin instantly.

Mechanical Properties

Mechanical properties of silage film are determined based on tests performed with the use of a device simulating the operation of a wrapping machine in laboratory conditions.

- During the Quality test, the strength and quality of the film are checked on a guaranteed stretch

- The Ultimate test determines the maximum stretch [%] when the film starts to rupture

- The Puncture test determines the force [kg] needed for puncturing the film

- The Retention test determines the maximum force [kg] exerted by the film in reaction to a point pressure

| Thickness (μm) | 20 | 25 | 30 |

|---|---|---|---|

| Stretch (%) | 300 | 350 | 400 |

| Stretch before rupture (%) | 330 | 380 | 430 |

| Puncture force value (kg) | 1.99 | 2.18 | 2.55 |

| Load retaining force value after 60 s (kg) | 1.26 | 1.42 | 1.78 |

*Guaranteed stretch of the silage film is determined in laboratory conditions. The way the film behaves on a wrapping machine depends on individual wrapping machine settings and the type of load being wrapped.

The film maintains its physicochemical properties for up to 12 months when storing the product in the conditions of average yearly insolation of 100 kLy.